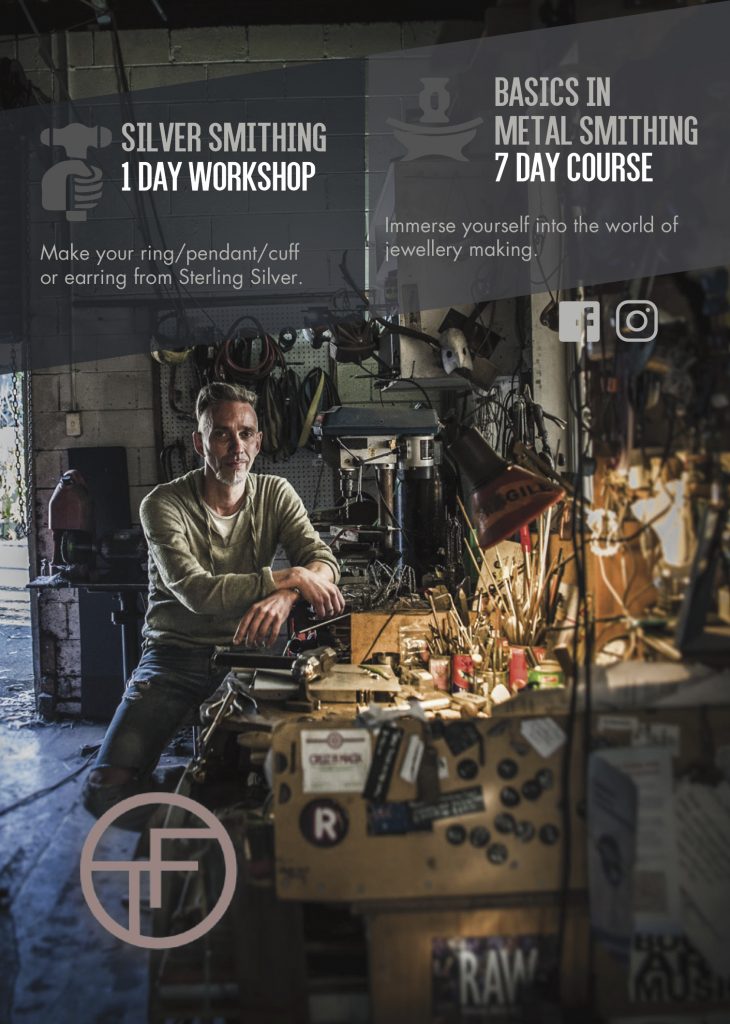

Classes

We offer classes in metalsmithing, jewellery making, and more at our Bangalow location. Here’s information on our currently available lessons and classes.

We offer classes in metalsmithing, jewellery making, and more at our Bangalow location. Here’s information on our currently available lessons and classes.

August 2, 2019

Posted by Thomas Frank

Every first Saturday in the months. See for dates and booking here https://www.eventbrite.com.au/e/1-day-workshop-make-your-own-sterling-silver-jewellery-tickets-62137313377

Hope to see you there, Thomas

Relates to Classes News Thomas Frank

May 26, 2019

Posted by Bruce Pringle

Melt and pour! The lesson consists of three hours intensive, one on one instruction, with a further 2 hours of supervised solo practice.

Full Fee, $300, includes materials.

Book now , call 0409960614 or Email bruce@brucepringle.com

A “one on one” lesson in traditional Jewellery sand casting techniques that will result in competency in the basic techniques.

This lesson consists of three hours intensive instruction, with a further 2 hours for solo practice with Bruce available to answer questions as needed, for a cost of $300

He teaches the technique of sand casting jewellery, using “green” sand.

This is similar to the popular proprietary product, “Delft Clay”,(an oil sand), sold in most jewellery supply shops.

Green sand (so named because it is wet, like green wood is wet), Is made up of a fine sand with a percentage of Bentonite clay. (between 5% and 15%, depending on the sand) and a little water to make it damp.

Bruce will start with a demonstration of the process of packing the “master” into the flask through to pouring the molten metal.

You will work side by side with Bruce, to make and pour your own casting… This will be repeated twice.

Your first piece cast will be of a small hare, in bronze and the second, a plain silver ring.

After this, you will have the opportunity to further practise the skill for a couple of hours, using your own “master”.

(This “master” could be something like an ornate button you may have, a seed pod, a medallion or something similar).

Once, having achieved competency, the average time taken to complete a casting, from packing the flask to pouring the metal is about 30 minutes.

* In foundry work, the terms cope and drag refer respectively to the top and bottom parts of a two-part casting flask. The flask is a wood or metal frame, which contains the molding sand, providing support to the sand as the metal is poured into the mold.

About Bruce Pringle, Metalsmith

Bruce is an experienced and passionate teacher and a self taught metal smith of some 40 years experience.

A jewellery maker, Silversmith, a Decorative Blacksmith (30 years), a knife maker, foundry worker, (both sand casting and lost wax), Steel and Bronze sculptor, Stainless steel utensil maker, skilled in electro etching, welding and Plasma cutting.

This site is using the Handgloves WordPress Theme

Designed & Developed by George Wiscombe